TRACE n TRACK

Trace n Track is Gazelle Information Technologies pioneer IoT Solution specifically researched and developed to help organizations in their endeavor towards Supply Chain Digital Transformation.

Gazelle Digitals team have developed a technology to generate Unique encrypted QR codes and then to maneuver and utilize the data stored in it till the end of its life for various purposes of Warehouse, Trace, Track, Counterfeits, Aftermarket etc. in Supply Chain and many other processes – giving it a true Dynamic character…

Looking to Implement Trace n Track in your Supply Chain?

Key Highlights of our Trace n Track Solution

- Complete understanding of the use case and applications

- Significant reduction in costs, redundancy and errors by automation

- Great experience in developing sustainable social welfare solutions using IoT, giving us great exposure to various use cases

- Leveraging new cutting-edge technologies like Blockchain to develop IoT solutions and products

- Pick, Pack and Ship the Products accurately against Sales Orders and integrate with ERP for Invoicing

- Track Stock positions and movements across Distribution Channels and monitor infringements

- Product level identity enable after market operations – Loyalty/Promotions, Warranty, Servicing, Counterfeits

- Role Based functional Accesses and Total Data Security in the entire system through strong E2E encryption

Salient Feature of Trace n Track

USE CASE CUSTOMISATION

DIGITAL TRANSFORMATION

SUSTAINABLE SOLUTION

MEASURABLE BENEFITS

SCALABILITY OF IMPLEMENTATION

Looking to Implement Trace n Track in your Supply Chain?

Who needs it

Organisations with exposure to complex supply chain processes

Organisations where product life cycle visibility is required

Organisations which require precise and quick exchange of information

Business which operate Globally or from Multiple Locations

Businesses looking to fulfill Statutory Requirements

Businesses looking for Digital Transformation of Supply Chain

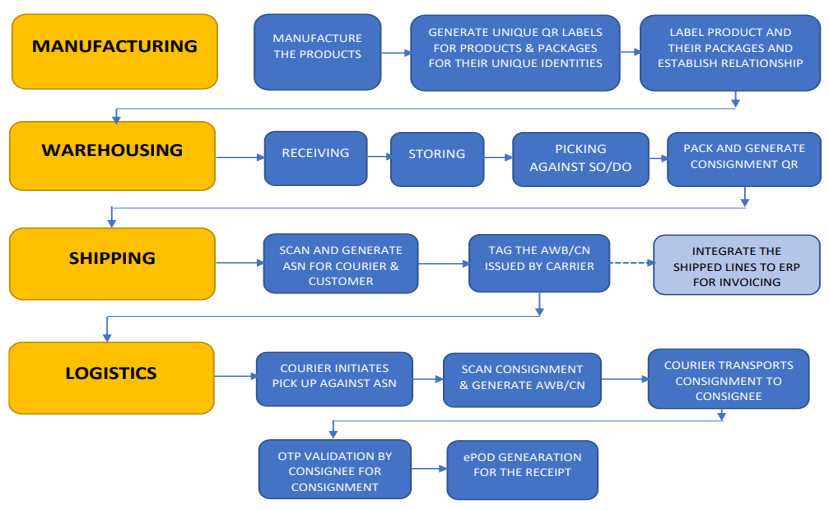

Process Flow of Trace n Track

Gazelle's Trace n Track Solution at a Glance

- Unique Dynamic QR Code is generated through our platform, which remains unique through out its life cycle and can not be ever duplicated due to very strong Encryption.

- Symmetric-key algorithms used for high level encryption of the QR Code to secure the data therein. The data can only be decrypted through our process given in the Gazelle Digitals

App. This feature acts as a deterrent towards Counterfeiting - At the time of manufacturing, each product will be tagged with these uniquely generated QR Codes having unlimited data set of the Product encoded in it, as the Primary package

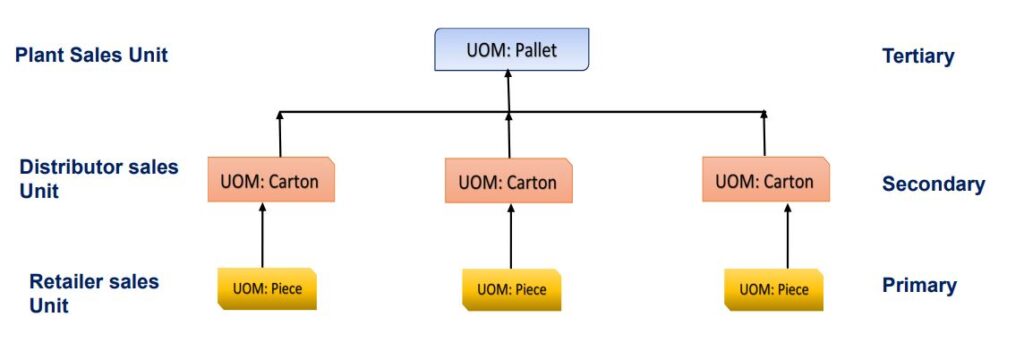

- Like wise unique QRs are generated for the Secondary and Tertiary packages – Carton and Pallet

- Unique QRs are also used for Warehouse locations, Consignment/Invoice documents and others..

- Can handle Multi Level Packaging

- Dynamically set Packaging levels and generate separate QR codes for each

- Can handle ‘n’ levels of packaging Hierarchy

- Multiple UOM (Selling units) can be handled

- An unique master QR Code would be generated for each stock location in the Warehouse

- For stocking in a Warehouse location the Store personal would use Gazelle Digitals Android App to first scan the location and then keep on scanning each product QR code which he is storing there.

- Thus the products stored in each Stock location could be easily tracked, along with its aging

- While Picking the SKUs against a Delivery Order a Picking List based on FIFO and other logics could be generated in our system, based on which the Picker goes to those Stock Locations and uses Gazelle Digitals App to scan all those required SKUs and pick them for delivery.

- Along side is a sample screenshot for Picking process through mobile app

- For a Sales/Transfer Order a Pick list is generated from the Gazelle Digitals Web App for the available SKUs to be Picked, Packed and Shipped

- Picking is the process of manual scanning the product QR through Gazelle Digitals Mobile App to be picked and create a Packing List which needs to be shipped.

- The required quantities of the Sales/Transfer Orders are picked from the Warehouse locations and placed on the Shipping Dock to be Packed and Shipped

- The Picked quantities are tallied and the Packing List generated for the items to be finally shipped, to which the Carrier document (CN/AWB) is tagged

- After completion of picking, a downloadable Packing List will be generated based on which the Consignments will be loaded by the Carriers / Couriers for transportation

- Against the Carrier/Courier CN / AWB the Consignment QR is generated which will scannable by the Consignee which could be a Depot, Distributor or the end Customer

- The system has a functionality to generate Advance Shipment Notices (ASN)

- The ASN simultaneously gets cued to the Courier on one hand and also to the Consignee (the Depot or the Distributor or the end Customer) on the other

- The sample screens of Gazelle Digitals App for the Courier and the Consignee are shown alongside

- Against a ASN the Courier company deputes a Pickup guy to pick the Consignment by issuing the AWB

- The same ASN on the Consignee’s view first gives the intimation that a Consignment is getting shipped giving all details of the contents and then updates all its movements

- Finally an OTP is exchanged between the Courier and the Consignee, which in turn generates a ePOD in the Consignor’s Application

- Multiple After market services could be handled through our Gazelle Digitals App

- Alongside some of the screens for Loyalty program and Warranty management are displayed

- Effectively manage Product Returns/Recall and tracing back to the supply source

- Other options could be to manage and record entire servicing history of an Equipment

- Counterfeit checks through combination of Product authentication and Geo location

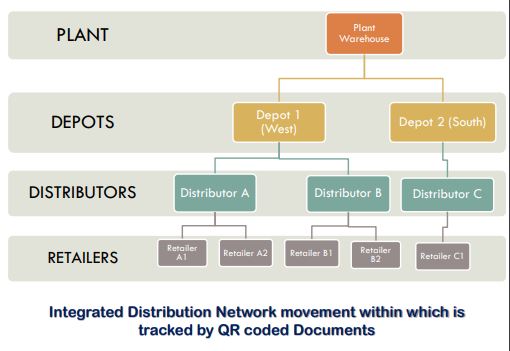

- Trace n Track is an integrated Supply Chain Management system

- Detailed Inventory tracking at each levels of the Stocking echelon will available if those levels are made part of the system

- Order promising and Inventory management becomes easily manageable at any level of the Distribution hierarchy

- Channel infringement could be easily tracked improving Demand Planning and eliminating Stock out or Over stocking

- The final consumption through the retailers are tracked through GPS integrations

Multiple information could be chained on the QR Code used at different levels..

- Because of the uniqueness of the QR code and its identity maintained at our Servers, any amount of data related to that QR could be chained through encryption and only retrieved by Gazelle Digital Apps

- As the Product movement across the Distribution network will be tracked by its QR, this will deter infiltration and unauthorized movements enabling strongest Channel management compliance

- The unique ID behind the QR code can only be decrypted by our App, this will act as a deterrent to any duplication or counterfeiting and also as the information security

- As multiple packages of the Product will also have QR codes assigned to each of them, the relationship amongst one another is chained which is ultimately chained to a Shipment QR

- Thus a product in a Consumers hand could easily be traced to its entire journey and also when the Customer scans it by Gazelle Digital Apps for Loyalty redemption its location could also be tracked

Looking to Implement Trace n Track in your Supply Chain?

Key Advantages of Gazelle's Trace n Track IoT Solution

01

Absolute Visibility in Supply Chain

02

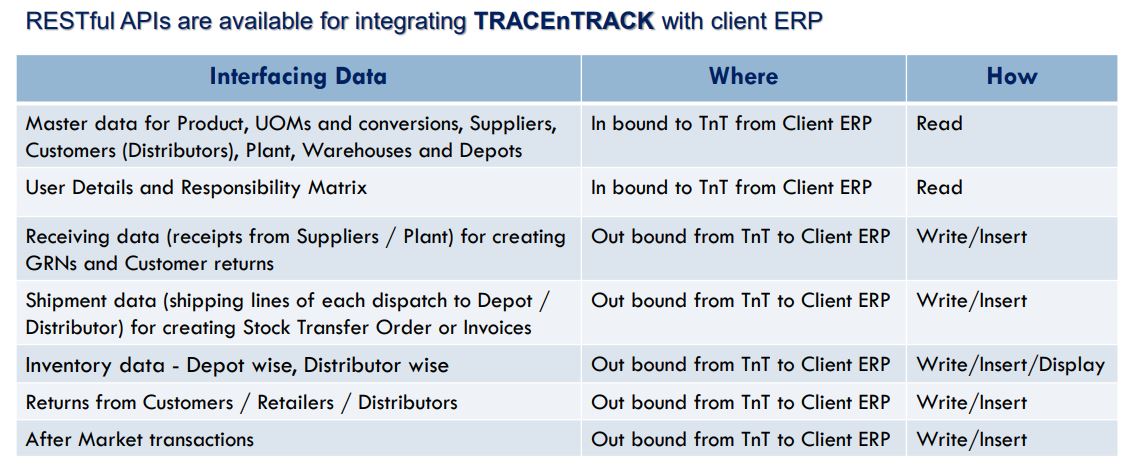

Easy Integration with Existing ERP

03

Covers Entire Product Lifecycle

04

Third Party Integration Enabled

05

Global Inventory View

06

Loaded with Security Features

Request a Call Back for Trace n Track Implementation.

Would you like to speak to one of our supply chain advisers over the phone? Just submit your details and we’ll be in touch shortly.

You can also email us if you would prefer.