How To Transform And Optimize Your Supply Chain Network Design For The Future?

Planning and deploying a robust supply chain network will position your company for growth.

For a quite long-time, mathematical optimization has been the go-to tool for supply chain network design. This AI technology is utilized by companies across the business spectrum to automatically determine the optimal configuration of their supply chains.

In this article, we walk you through the key steps you need to take to optimize the design of your supply chain network and the future of Supply chain Networks.

How Supply Chain Network Design happens right now?

There are mainly two types of supply chain network that is widely adopted.

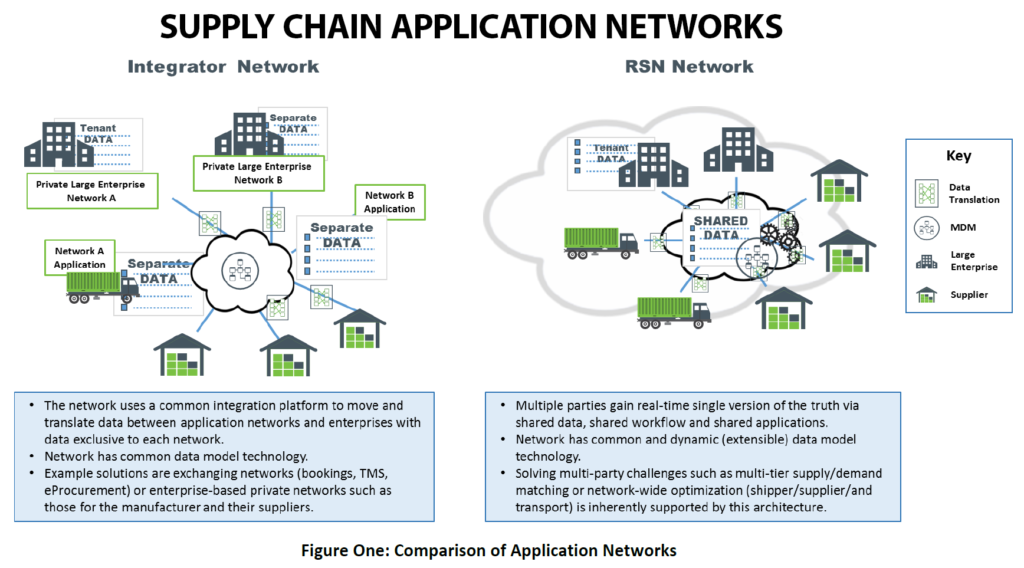

One is Integrator Networks (IN) and the other is Real- time Single Version of the Truth Networks (RSN).

Integrator Network—these are networks that have been built over the long term through acquisitions. Thus, within their offerings are a set of separate networks that are integrated between applications and users/tenants. A common integration platform is delivered.

Real-time SVOT (Single Version of the Truth) Network—these are networks that have by and large been organically developed with a single database and single processing engine. This is a many-to-many technique in which all tenants share the same ledger-like, multi-enterprise data store—as well as sharing the same multi-party process execution. Below is a comparison between these two supply chain application network approaches.

Problems in Supply chain network

Increased Costs throughout the Supply Chain

Profit margins are under pressure as costs creep up all through the supply chain network. These costs come from many areas, and a lack of accountability and visibility for reducing them can result in rising operational expenses.

Supply Chain Complexity Due to Multiple Channels to Market

Consumers buy products across multiple channels, and as routes to market increase, the underlying supply chain must adjust. Supply chain professionals need to develop variations on supply chain processes to address each of the channels:

- Ecommerce websites selling directly to consumers require local logistics and fast last mile delivery.

- Traditional retailers and wholesalers need large warehouse locations close to major metropolitan areas, combined with accurate inventory control to ensure product availability.

- Third-party marketplaces like Amazon require an in-depth understanding of fulfilment options and close compliance with their terms and conditions.

- Drop shipping retail requires fast global services so that consumers receive goods quickly.

How to solve these problems

Keep liquidity in your business

Protect your business with flexible access to funds. After all, having cash on hand is often the difference between meeting demand and running out of stock.

Diversify sourcing in your supply chain strategy

Broaden your range of sourcing, may be geographically, to increase choice and abundance within your supply chain. By developing a number of supplier relationships, it’s easier to become more adaptable and adjust to a constantly changing market (i.e. during a long-lasting and prolonged pandemic that alters the entire global economy).

Identify alternative shipping ports

Take leverage on your tracking routes by seeking out alternative ports to meet your fulfilment needs and stay on schedule, regardless of unforeseen events or a sudden spike in customer orders.

Improve demand forecasting

Without fail, the best way to develop & improve forecasting is by using automations to calculate these metrics on your behalf. Ecommerce sellers are always looking for a balance between their stock levels, warehousing costs, and the demand from their customers to prevent stock outs or inventory shortages.

How does it work? Here are the Steps to optimise and Transform your Supply chain Network Design

Clearly define your objectives.

No Supply chain manager is likely to improve all aspects of their logistics and distribution network all at the same time. The most critical step in designing supply chain networks is to identify your primary objectives. A partial list of critical decisions you might consider is:

- What level of customer service does my market demand?

- What modes of transport should be used to balance cost vs. customer service objectives?

- Which warehouses should supply products to which customers?

- Where should inventory be stored and how much stock should I be carrying of each product?

- Which manufacturing plants should be making product for which customers/warehouses?

- What routes should I be using to obtain product from source to destination?

- Are there opportunities for combining together resources that have been overlooked?

Identify your objectives as those decisions that are most important to the profitability and those that you can do something about.

Gather supporting data

In order to make smart decisions, you need solid data to support those decisions. This step is usually the most time-consuming part of the process. The good news is that the data is available and reusable for future use.

Model your supply chain network

Today’s technology can help you make more promising decisions as there are many vendors offering supply chain network optimization tools. Alternatively, you can cost-efficiently configure your own. Choose wisely, as all software is not created equal.

Analyse your supply chain network

Using supply chain optimisation tools to make better decisions for your business requires good old-fashioned analysis, such as Profit Point’s Strategic Network Analysis Program (SNAPTM). Depending on people to leverage the advantages of technology is the path to success.

Implement and refine

The supply chain network analysis and design process is not a fixed process. Successful ideas are implemented and cost savings are realized. And then things might change: a large new customer is added at a new location, more production capacity is added, demand takes a nosedive, or raw material prices swing dramatically. So there is a need to refine and overlook the process of supply chain network.

What lies ahead for Supply Chain network in the future?

Though technology and automation have been involved in the supply chain for quite some time, what once seemed impossible is now becoming part of a new reality, from warehouse robotics to artificial intelligence (AI).

Here are the top five supply chain technology trends in the works that continue to evolve.

● Demand forecasting

● Artificial intelligence (AI)

● Self-driving trucks

● Warehouse robotics

● Supply chain security