Table of Content

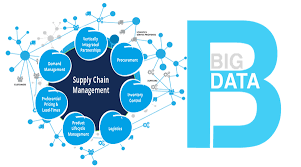

Supply Chain – Advanced Analytics For Supply Chain Management

• What is meant by advanced analytics and what are some of the advanced analytics techniques?

Autonomous or semi-autonomous examination of data or content using sophisticated techniques and tools is known as advanced analytics. Typically beyond those of traditional Business Intelligence (BI), to discover deeper insights, make predictions, or generate recommendations.

Some of the advanced analytics techniques are

1. Descriptive analytics – These are the standard historical reporting metrics. Some of the measures used under this sort of analysis are

- Inventory turnover – Inventory sold and replaced during a given period by a company through a financial ratio. A company can then divide the days in the period by the inventory turnover formula to calculate the days it takes to sell the inventory on hand.

- Number of inventory days held – The average time a company keeps its inventory before it is sold. To calculate days in inventory, divide the cost of average inventory by the cost of goods sold, and multiply that by the period length, which is usually 365 days.

- Inventory turnover ratio – Inventory turnover ratio, defined as how many times the entire inventory of a company has been sold during an accounting period, is a major factor to success in any business which is in possession of the inventory. It shows how well a company manages its inventory levels and how frequently a company replenishes its inventory.

- Percentage orders delivered on time – There are different ways of measuring OTD (On Time Delivery) by different organizations. In basic terms, OTD is a calculation of the amount of shipments delivered on time to the customer in relation to the total number of orders shipped. If the number is below the benchmark, it likely means there are deeper issues that need addressed.

- Inventory wastage – Inventory waste refers to the waste produced by unprocessed inventory. This includes the waste of storage, the waste of capital tied up in unprocessed inventory, the waste of transporting the inventory, the containers used to hold inventory, the lighting of the storage space, etc.

2.Diagnostic analytics – This is the next level of supply chain analytics which is known as diagnostic. It provides insight as to why targets were missed. A degree of added intelligence is required. Diagnostic analytics determines the real reasons for poor performance so corrective action can be taken. As before, diagnostic analytics identifies only the reason, not the solution.

3.Predictive analytics – This form of analytics uses historical data, advanced mathematics and complex algorithms to determine future trends, allowing organizations to adjust strategies beforehand. Up to 30 percent of supply chain professions say they use predictive analyticsto determine future trends.

4.Prescriptive analysis – Knowing what to do is known as prescriptive analytics builds on the base provided by predictive analytics. It uses advanced modeling and solver software to run complex scenarios to determine optimal supply chain decisions to issues and trends identified by diagnostic, descriptive and predictive analytics

• How does supply chain advanced analytics help in supply chain management?

- Supply chain analytics is an essential element of supply chain management (SCM). Choosing supply chain analytics software to improve forecasting and efficiency and be more responsive to customer needs is an important goal of supply chain analytics. For example, predictive analytics on point-of-sale terminal data stored in a demand signal repository can help a business anticipate consumer demand, which in turn can lead to cost-saving adjustments to inventory and faster delivery.

- End-to-end supply chain analytics requires bringing information together across the procurement of raw materials and extends through production, distribution and aftermarket service and hence needs to be achieved. This depends on effective integration between the many SCM and supply chain execution platforms that make up a typical company’s supply chain. The goal of such integration is supply chain visibility: the ability to view data on goods at every step in the supply chain. For example: a procurement system can automatically place purchase orders with suppliers when inventory is low; an order management system can identify the cost-effective fulfillment option for a particular order; and a warehouse management system can help an employee pick, pack and prepare an order for shipment in the most efficient manner.

- Inventory costs can be reduced through smarter demand sending by combining all of your previous order data with real-time market analyses to create dynamic demand forecasts that prove much more successful at predicting changes in the demand landscape than human supply chain planners. The most critical is inventory management. A company without a robust analytics workflow might expect a customer to place a large parts order in the near future (and thus stock their warehouse with those parts) only to find that the order size had decreased from the previous year (meaning that the parts would just continue to take up valuable space). With better demand sensing via advanced analytics, by contrast, the company could have anticipated these demand changes by reducing their production of the part in question, thereby freeing up valuable storage space.

- Analyzing your existing freight network usage to find potential areas for improvement, improved demand predictions can help you to plan your transports in advance with added certainty. The modes of transport can involve truck, ship, train and plane. Trains are the most fuel-efficient method of transporting goods across land. Trains are two to four times more efficient at transporting freight than conventional trucks, depending on the cargo, and a single freight train can carry the equivalent of 280 truckloads.

• How to use supply chain advanced analytics in supply chain management?

Supply chain analytics is used by Sales and operations planning to match a manufacturer’s supply with demand by generating plans that align daily operations with corporate strategy. Supply chain analytics is also used to do the following:

Improve risk management throughout the supply chain by identifying known risks and predicting future risks based on patterns and trends.

Increase planning accuracy by identify factors that increase or decrease demand through analyzing customer data.

Improve order management by consolidation of data sources to assess inventory levels, predict demand and identify fulfillment issues;

Streamline procurement by organizing and analyzing spending across departments to improve contract negotiations and identify opportunities for discounts or alternative sources; and

Increase working capital by improving models for determining the inventory levels required to ensure service goals with minimal capital investment.

• Conclusion: How to choose the best supply chain data analytics?

The best Supply chain management (SCM) software centralizes processes including raw material acquisition and product designing to ensure inventory and final distribution at the appropriate time and location while minimizing system-wide costs, improving customer satisfaction and promoting efficiency.

Some tips to choose the best software are:

- Total cost of ownership must be estimated. Financial details must be dived deep into and add up costs of support, customization, and upgrades. The final number can be impressively larger than the initial purchase price you are ready to pay.

- Investing in a large, stand-alone SCM system should be avoided, instead you can start with implementing a few modules addressing major problems and bottlenecks across your supply chain.

- Your existing software can be complemented with new SMC components and adds-on. Chances are developing a custom solution tailored for your unique case will be cheaper (at least in terms of time and effort) and bring more value than ready-to-use, but hard-to-integrate software with functionality that exceeds your needs.

- Domain focusis something you shouldn’t ignore. If SCM software is initially designed for a different industry, modification can be a tricky and money-consuming task.